Farhym combines all the necessary resources to implement the design needs of our customers.

We successfully master the challenge of processing a broad range of materials, applying very different processes, while maintaining a consistently high quality. Our interior systems are created from materials just as fiberglass, aluminium, wood and plastic, combined with a multitude of single components, representing a seamless fit to our customers’ vehicles.

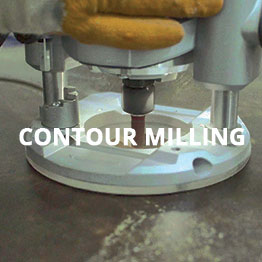

At our production sites, we offer milling, grinding and punching, horizontal and vertical sawing, paint preparation and painting, bonding of fabrics and foils, electrical assembly of lighting and audio systems, service sets and air conditioning control units, their functional testing, and the assembly of all components of the complete GfK and aluminium channels for direct installation of the entire system in the customer vehicles.

Our new paint shop, which was inaugurated in 2018, was built in accordance with European standards (EN 12215 and EN 13355) and state-of-the-art technology, and is a nationwide leader with its 56m2 spray booth. Here we can offer our customers the coating of even large-sized components.

Besides being experienced experts in the different fields of production, we have established a production control which guarantees efficient and smoothly synchronized coordination of all production processes. For our customers, this means reliable realisation of their order, even in large serial production, while always having the flexibility for customized small batch production, prototype construction and variations in the series production.

In the past, we could continually expand our production portfolio and adapt it to the requirements of our customers. With flexible employees and resources, we are therefore able to break new ground and provide you with all the technologies needed to implement your interior design solution.